Manufacturing Capability

|

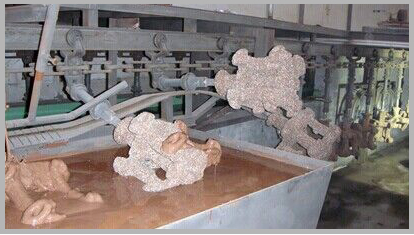

JBM is a company consists of Casting, Forging and CNC Machining capability. It has two casting production line, product range from 0.03KG-120KG. Casting process covers Investment Casting, Sand Casting and Lost Foam Casting. Wide range of material is available like Carbon Steel, Alloy Steel, Stainless Steel, Ductile Iron, Cast Iron. Cast tolerance controlled tighter than GB standard. CT4~5 for investment

casting, CT8-9 for sand casting, CT7-8 for lost foam casting.

|

|

|

Forged part is range from 0.1KG~60KG. Complicated structure can be produced. Materials are mainly for Carbon Steel and Alloy Steel, heat-treatment is applied. Our forging part can reach tolerance for CT9, which results in less material and machining that greatly reduced the manufacturing cost. Forging machine capacity is from 650 tons to 5000 tons, which can greatly meet your various part designs.

|

|

|

CNC and VMC with 4 axis machines enables us meet your

various requirements. Advanced equipments support us to provide customers with high precision parts. For batch production tolerances we can meet, Diameter tolerance is 0.02mm, Roughness reach Ra 0.6. True positions can meet 0.05mm. SPC, CPK measurement tools are also applied to production analysis. Special de-bur tool is applied for sharp edges. Ultra-sonic cleaning machine is used to remove grease, oil or any other dirty. Detailed Packing Instruction is prepared for each part before package to avoid any scratch, number mess or other packing errors.

|

|